- Business Process Management (BPM)Document Management System (DMS)Electronic Quality Management System (QMS)Risk, Governance & Compliance (GRC)Low Code Rapid Application Development (LC)Business Continuity Management (BCM)Enterprise Architecture (EA)Business Process Management (BPM)Document Management System (DMS)

- Document Control Overview

- AI Content Creation & Improvement

- Policy & Procedure Management (SOP)

- AI Content Mining Parser

- Collaboration & Governance

- Data Migration & Integration

- Interfacing Offline App

Electronic Quality Management System (QMS)

Electronic Quality Management System (QMS)- Quality Management System Overview

- Document Control & Records Management

- Audit & Accreditation Management

- Corrective & Preventative Action

- Quality Event (Non-conformity / Complaint/ Compliance)

- Risk Management

- Incident Management

- Environmental Health & Safety

- Product & Supplier Management (SCAR)

- Training Management

- Control Management

- Action Items Management

- Management Review

- FMEA

- Pharmacovigilance

- Data Migration & Integration

Risk, Governance & Compliance (GRC)

Risk, Governance & Compliance (GRC)- Risk, Governance & Compliance Overview

- Risk & Control Management

- Regulatory Compliance

- Collaboration & Governance

- Data Migration & Integration

- Interfacing Offline App

Low Code Rapid Application Development (LC)

Low Code Rapid Application Development (LC)- Low Code Automation Platform Overview

- Electronic Web Form Design (eFORMS)

- Database Table Entity Designer

- System Integration Designer

- Design & Manage Tasks

- Design & Manage BPMS Apps

- Custom Rules/Guards/Actions

- Electronic Services

- User Homepage

- BAM (Business Activity Monitoring)

- Custom Dashboard Design

- Data Migration & Integration

Business Continuity Management (BCM)

Business Continuity Management (BCM)- Business Continuity Management Overview

- Business Impact Analysis

- Disaster Recovery Simulation

- Action Item Management

- Mass Notification Management

- Asset Management

- Interfacing Offline App

Enterprise Architecture (EA)

Enterprise Architecture (EA) - IndustriesRegulatory ComplianceUse CasesLearning CenterFramework & PracticesIndustries

- Healthcare

- Medical Device Technology

- Life Science, Pharmaceutical

- Aerospace & Defense

- Airlines and Aviation

- Media & Telecommunications

- Government and Military

- Technology

- Energy

- Logistics & Port Operations

- Banking & Capital Markets

- Retail & Consumer

- Consulting

- Education

- Engineering & Construction

- Manufacturing

- Financial Services

- Insurance

- Chemicals

Regulatory Compliance- Regulatory Compliance

- ISO

- ISO 9001 (guide)

- ISO 9001:2026 (preparation)

- ISO 17025

- ISO 27000

- ISO 27001

- ISO27002

- ISO 42001

- EU AI Act

- SOC 2 Type 1 & 2

- Sarbanes Oxley

- GxP

- GRC

- Basel

- Digital Signature

- GDPR

- IFRS

- NIST SP 800-53

Use Cases

Use Cases- Quality Management System (QMS)

- Digital Transformation

- Continuous Improvement

- Governance, Risk & Compliance

- Knowledge Management

- System Deployment (ERP, CRM…)

Learning CenterFramework & Practices

Learning CenterFramework & Practices - AboutCustomer SuccessPartners

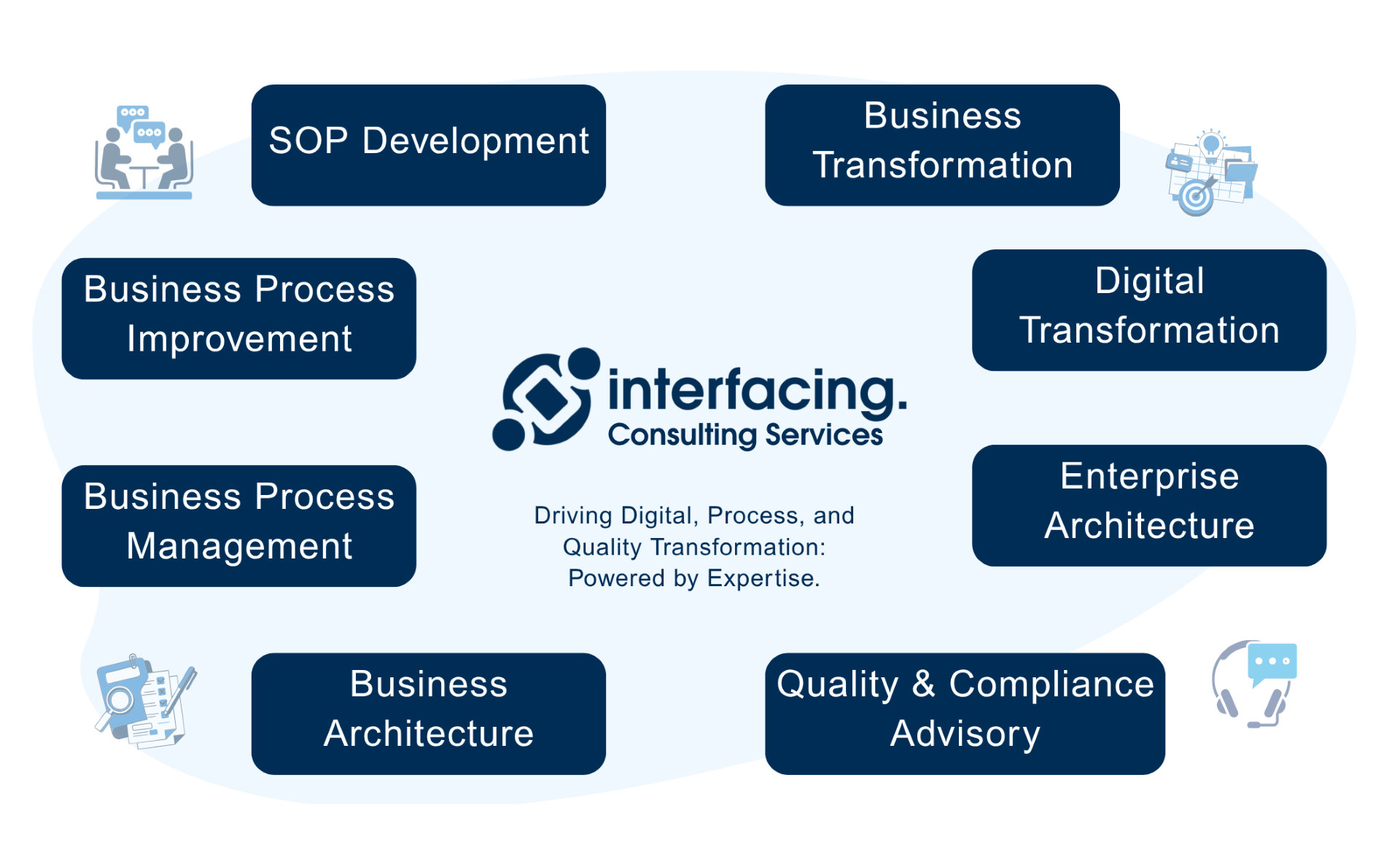

Process Improvement Services

Please Select contact form.

Improve your business processes with the help of Interfacing’s BPI Professionals.

Process Improvement

Business Process Improvement (BPI) is a discipline that is aimed to fine-tune organizations, resulting in more efficient productivity. BPI is significant today due to the constant expansion of technology especially in the business realm. It is important to stay up to date in technological infrastructure advancement in order to succeed. It allows organizations successfully produce high quality products and services while being cost-effective. Since it is a strategic planning process, it identifies points of weaknesses while adding value with improved operational performance which gives one an advantage in the competitive market. Implementing a business process improvement system will only add value to the organization.

Benefits

Productivity

Process improvement identifies and eliminates unnecessary waste. Through procedure redesign or process automation, it reduces tasks completion time with less man power, resulting in better allocation of time...

Staff

Engagement

Business Process Improve facilitates collaboration between all sectors of the workplace. Increased transparency will not only ease communication but also makes sure each employee is...

Automation

Automating will reduce redundant tasks as well as decrease the number of human errors produced. Proper monitoring and optimization of processes will result in consistent executions of tasks with minimized risks.

Standardization

Standardization helps in assuring the company is complying with regulations, industry and governmental standards. Regulatory compliance allows for a more organized and manageable workspace.

Methodology

Interfacing uses the Define, Measure, Analyze, Improve, Control (DMAIC) methodology. This encompasses a combination of the Lean and Six Sigma methods which allows for maximized benefits. This data-driven methodology lets us understand the problem, identify the root causes, and propose potential solutions.

DMAIC

DMAIC consists of 5 phases: Define, Measure, Analyze, Improve, and Control. Defining the problem allows for better understanding of the issue in order to properly execute the necessary steps towards a solution. The execution of each component allows for a better understanding of a situation, providing a road map to achieve goals more quickly and better management. Measuring the process performance and analyzing determines the root causes of weak points. The Improve and control phases eliminate the cause of poor performance and allow one’s organization to maintain a steady state of continuous improvement.

Lean

The Lean method is a customer focused approach that promotes amelioration of organizational operations by eliminating waste. The act of disposing unnecessary dross in a system maximizes not only customer experience and value but also the organization’s processes.

Six Sigma

The Six Sigma methodology provides tools to enhance organizational capabilities. It reduces defects and process variations while increasing performance and improvement of quality. Applying these tactics will result in processes with controlled and improved performance.

Although each methodology can perform well alone, at Interfacing we implement a combination of all three to maximize their potentials and this allows us to provide only the best outcomes for our clients.

Deliverables

Phase 1

1. Define the problem and the objectives

2. Mapping out workflow

3. Target problematic processes

4. Define the responsibilities and points of contact of the system

5. Collect data and analytics

6. Cause and effect analysis (root of the problem)

7. Data check of root causes

8. Potential solution recommendations

Phase 2

1. Project plan (resources, schedule, impact, risk)

2. Cost-benefit analysis

Phase 3

1. Pilot the solution

2. Change management and training

3. Implement the solution

4. Control and monitoring plan (including process measures)

5. Lessons learned

Why Choose Interfacing?

With over two decades of AI, Quality, Process, and Compliance software expertise, Interfacing continues to be a leader in the industry. To-date, it has served over 500+ world-class enterprises and management consulting firms from all industries and sectors. We continue to provide digital, cloud & AI solutions that enable organizations to enhance, control and streamline their processes while easing the burden of regulatory compliance and quality management programs.

To explore further or discuss how Interfacing can assist your organization, please complete the form below.

Documentation: Driving Transformation, Governance and Control

• Gain real-time, comprehensive insights into your operations.

• Improve governance, efficiency, and compliance.

• Ensure seamless alignment with regulatory standards.

eQMS: Automating Quality & Compliance Workflows & Reporting

• Simplify quality management with automated workflows and monitoring.

• Streamline CAPA, supplier audits, training and related workflows.

• Turn documentation into actionable insights for Quality 4.0

Low-Code Rapid Application Development: Accelerating Digital Transformation

• Build custom, scalable applications swiftly

• Reducing development time and cost

• Adapt faster and stay agile in the face of

evolving customer and business needs.

AI to Transform your Business!

The AI-powered tools are designed to streamline operations, enhance compliance, and drive sustainable growth. Check out how AI can:

• Respond to employee inquiries

• Transform videos into processes

• Assess regulatory impact & process improvements

• Generate forms, processes, risks, regulations, KPIs & more

• Parse regulatory standards into requirements

Request Free Demo

Document, analyze, improve, digitize and monitor your business processes, risks, regulatory requirements and performance indicators within Interfacing’s Digital Twin integrated management system the Enterprise Process Center®!

Integration

Discover how we helped other Companies succeed