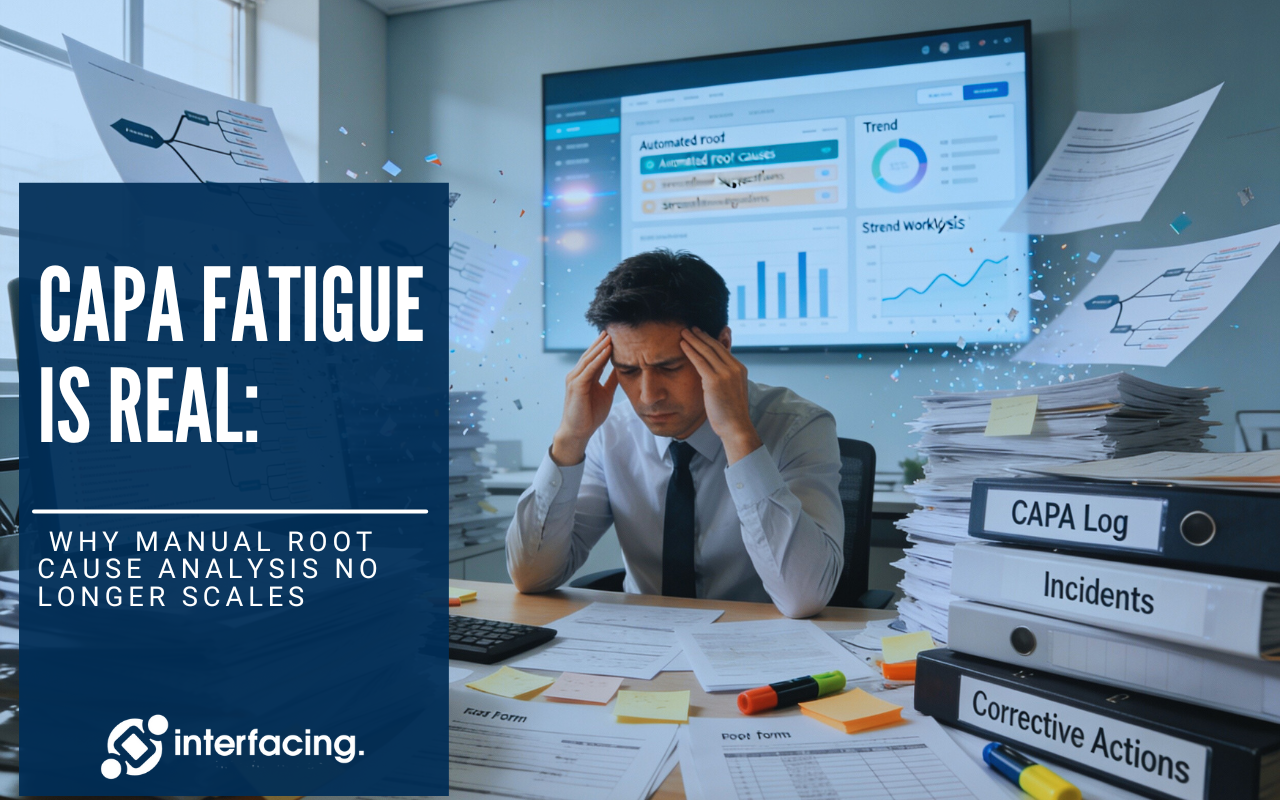

Manual root cause analysis breaks down at scale. CAPA fatigue is a signal that quality systems need deeper process intelligence, not more paperwork.

Corrective and Preventive Action was never meant to be exhausting. In theory, CAPA exists to close the loop between issues and improvement. In practice, for many organizations, it has become a grinding cycle of investigations, meetings, documentation, and déjà vu.

The symptoms are familiar. The same issues resurface under slightly different labels. Root cause analyses feel rushed or superficial. Investigations take longer than they should, yet confidence in their conclusions keeps declining. Teams comply, but they do not improve.

This is not a failure of discipline. It is a failure of scale.

CAPA fatigue is what happens when manual root cause analysis is pushed beyond what it was ever designed to handle.

When Root Cause Analysis Becomes a Bottleneck

Traditional root cause analysis relies heavily on human interpretation. Teams gather evidence, review documents, interview stakeholders, and attempt to reconstruct what went wrong. For isolated events, this approach can work well.

The problem emerges when volume increases.

As organizations grow, processes multiply, regulations expand, and operational complexity deepens. Deviations no longer occur in isolation. They appear as patterns across sites, products, suppliers, and systems. Manual analysis struggles to keep up because it depends on individuals connecting dots that span far beyond a single incident.

What often gets labeled as “human error” or “process non-compliance” is, in reality, a signal of deeper systemic issues. But without visibility across processes and historical data, those signals are easy to miss.

CAPA becomes reactive instead of corrective.

The Illusion of Thoroughness

One of the most dangerous aspects of manual CAPA is that it can look rigorous while remaining shallow.

Templates are filled out. Fishbone diagrams are drawn. Five Whys are completed. Audit trails are maintained. On paper, everything appears compliant.

Yet when similar issues recur, the uncomfortable truth surfaces. The analysis addressed the symptom, not the system.

This is not because teams are careless. It is because manual methods are fundamentally limited in their ability to detect trends, correlations, and weak signals across time and across processes. Humans are excellent at judgment. They are far less reliable at pattern recognition at scale.

As CAPA volume increases, cognitive load increases with it. Fatigue sets in. Shortcuts follow.

Why Manual CAPA Does Not Scale in Modern Environments

Modern quality environments generate more data than ever before. Process performance metrics, audit findings, training records, change histories, supplier data, and risk assessments all contain pieces of the root cause puzzle.

Manual analysis treats these sources as separate inputs. Someone has to remember to look at them, interpret them, and connect them.

Artificial intelligence changes the equation, but only when it has the right foundation.

AI is not valuable because it automates paperwork. It is valuable because it can analyze relationships humans cannot reasonably track on their own. But when quality events, processes, and risks live in disconnected systems, AI is forced into the same blind spots as manual analysis.

This is why many organizations feel stuck. They invest in QMS tools, add more rigor to CAPA workflows, and still experience fatigue. The underlying operating model has not changed.

From Investigation to Insight

The shift away from manual root cause analysis is not about replacing quality professionals. It is about augmenting their expertise with systems that can surface insight earlier and more reliably.

When CAPA is connected directly to process architecture, historical performance data, and risk context, root cause analysis becomes less speculative. Patterns that once took months to uncover emerge quickly. Recurring issues reveal their common origins. Preventive actions become truly preventive.

This is the difference between investigating incidents and understanding systems.

The Real Cost of Ignoring CAPA Fatigue

Organizations often accept CAPA fatigue as inevitable. It is not.

What feels like exhaustion is often a signal that the system supporting quality has reached its limits. Manual root cause analysis worked when complexity was lower and data volumes were manageable. Those conditions no longer exist.

In an environment where regulators expect evidence-based decisions and leadership expects insight, CAPA must evolve from a compliance exercise into an intelligence-driven capability.

The question is no longer whether CAPA is being performed.

It is whether it is actually working.

How Interfacing Helps

Interfacing addresses CAPA fatigue by changing the structure in which CAPA operates.

Instead of treating corrective and preventive actions as isolated quality records, Interfacing embeds CAPA directly within an AI-driven Integrated Management System. Quality events are linked to the processes that produced them, the risks they expose, the controls meant to prevent them, and the training and documentation that support execution.

This integrated foundation allows root cause analysis to move beyond individual incidents. AI can analyze historical patterns across processes, identify systemic contributors to recurring issues, and highlight where preventive actions are likely to have the greatest impact.

Interfacing’s Quality Management Software supports CAPA as part of a continuous improvement cycle rather than a standalone workflow. Investigations are informed by real operational context, not just the information available in a single record.

At the same time, Interfacing’s Business Process Management capabilities ensure that corrective actions are not abstract recommendations. They are tied to actual process changes, with traceability to owners, controls, and performance outcomes.

The result is not faster CAPAs for the sake of speed. It is fewer repeat issues, stronger preventive actions, and a quality function that spends less time firefighting and more time improving.

Interfacing does not eliminate the need for human judgment. It removes the manual burden that causes judgment to fail under scale.

Why Choose Interfacing?

With over two decades of AI, Quality, Process, and Compliance software expertise, Interfacing continues to be a leader in the industry. To-date, it has served over 500+ world-class enterprises and management consulting firms from all industries and sectors. We continue to provide digital, cloud & AI solutions that enable organizations to enhance, control and streamline their processes while easing the burden of regulatory compliance and quality management programs.

To explore further or discuss how Interfacing can assist your organization, please complete the form below.

Documentation: Driving Transformation, Governance and Control

• Gain real-time, comprehensive insights into your operations.

• Improve governance, efficiency, and compliance.

• Ensure seamless alignment with regulatory standards.

eQMS: Automating Quality & Compliance Workflows & Reporting

• Simplify quality management with automated workflows and monitoring.

• Streamline CAPA, supplier audits, training and related workflows.

• Turn documentation into actionable insights for Quality 4.0

Low-Code Rapid Application Development: Accelerating Digital Transformation

• Build custom, scalable applications swiftly

• Reducing development time and cost

• Adapt faster and stay agile in the face of

evolving customer and business needs.

AI to Transform your Business!

The AI-powered tools are designed to streamline operations, enhance compliance, and drive sustainable growth. Check out how AI can:

• Respond to employee inquiries

• Transform videos into processes

• Assess regulatory impact & process improvements

• Generate forms, processes, risks, regulations, KPIs & more

• Parse regulatory standards into requirements

Request Free Demo

Document, analyze, improve, digitize and monitor your business processes, risks, regulatory requirements and performance indicators within Interfacing’s Digital Twin integrated management system the Enterprise Process Center®!

Trusted by Customers Worldwide!

More than 400+ world-class enterprises and management consulting firms