Introduction

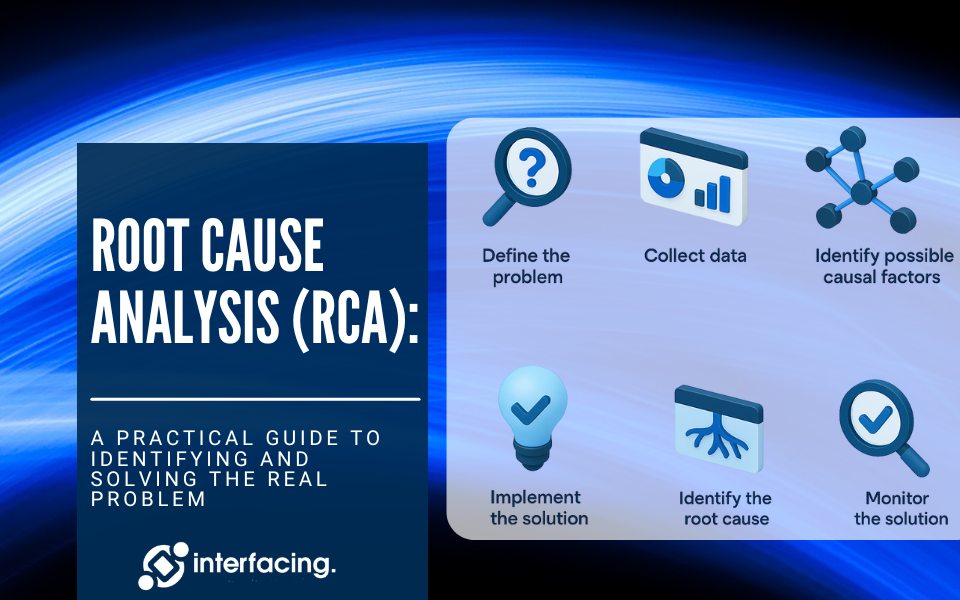

Recurring issues drain time, resources, and customer trust. Root cause analysis (RCA) is a systematic method for identifying the underlying cause of a problem, not just its symptoms. When used correctly, RCA helps organizations reduce risk, improve quality, and create sustainable solutions, especially when paired with simulation tools to test potential fixes.

What is Root Cause Analysis?

Root cause analysis is a structured problem-solving approach used to identify the origin of an issue. Instead of repeatedly treating symptoms, RCA digs deep to uncover the “why” behind a problem, enabling organizations to implement corrective actions that prevent recurrence.

RCA is foundational in quality management systems and is essential for compliance in industries like life sciences, aerospace, and manufacturing.

When Should You Use Root Cause Analysis?

You should conduct a root cause analysis when:

A problem keeps recurring

An incident causes significant downtime, cost, or risk

Regulatory requirements demand a thorough investigation

CAPA processes are triggered in a compliance framework

5 Key Steps to Root Cause Analysis

Clearly Define the Problem

Identify the who, what, when, where, and how of the issue. Include measurable impacts.

Gather Evidence

Collect data from process logs, reports, and interviews to establish timelines and contributing factors.

Identify Possible Root Causes

Apply tools like:

- 5 Whys Analysis

- Fishbone (Ishikawa) Diagrams

- FMEA (Failure Mode and Effects Analysis)

- Fault Tree Analysis

Validate the Root Cause

Verify that the identified cause explains the problem and is supported by data.

Design and Simulate Corrective Actions

Use BPMN 2.0 process simulation to test how proposed changes affect the larger system — before implementation.

How Process Simulation Supports RCA

Simulation takes root cause analysis from theory to validation. By modeling your corrective actions through BPMN 2.0 simulations, you can:

Forecast the impact of changes

Identify unintended consequences

Prevent shifting bottlenecks

Confirm the fix will actually solve the problem

RCA Tools Comparison

Tool | Purpose | Best Use Case |

|---|---|---|

| 5 Whys | Simple analysis | Manufacturing or operations |

| Fishbone Diagram | Cause categorization | Complex service issues |

| FMEA | Risk anticipation | Product design, life sciences |

| Process Simulation | Testing solutions | Process changes, compliance |

How AI Elevates Root Cause Analysis

Modern RCA is enhanced by AI-powered tools that:

Automatically detect process deviations

Identify trends across historical data

Recommend likely root causes

Accelerate RCA workflows with intelligent automation

Combining AI with simulation ensures you’re fixing the right problem in the right way.

How Interfacing Helps

Interfacing’s Digital Business Platform brings root cause analysis into your daily operations with:

Visual process mapping (BPMN 2.0)

Integrated CAPA management

AI-driven process mining

BPMN simulation to test corrective actions

Centralized, audit-ready RCA documentation

Our platform empowers you to act on RCA findings confidently, with tools that ensure resolution is both effective and compliant.

Final Thoughts

Root cause analysis isn’t just about fixing what’s broken — it’s about transforming the way problems are approached. When RCA is supported by simulation and AI, it becomes a powerful driver of operational excellence, continuous improvement, and regulatory confidence.

Why Choose Interfacing?

With over two decades of AI, Quality, Process, and Compliance software expertise, Interfacing continues to be a leader in the industry. To-date, it has served over 500+ world-class enterprises and management consulting firms from all industries and sectors. We continue to provide digital, cloud & AI solutions that enable organizations to enhance, control and streamline their processes while easing the burden of regulatory compliance and quality management programs.

To explore further or discuss how Interfacing can assist your organization, please complete the form below.

Documentation: Driving Transformation, Governance and Control

• Gain real-time, comprehensive insights into your operations.

• Improve governance, efficiency, and compliance.

• Ensure seamless alignment with regulatory standards.

eQMS: Automating Quality & Compliance Workflows & Reporting

• Simplify quality management with automated workflows and monitoring.

• Streamline CAPA, supplier audits, training and related workflows.

• Turn documentation into actionable insights for Quality 4.0

Low-Code Rapid Application Development: Accelerating Digital Transformation

• Build custom, scalable applications swiftly

• Reducing development time and cost

• Adapt faster and stay agile in the face of

evolving customer and business needs.

AI to Transform your Business!

The AI-powered tools are designed to streamline operations, enhance compliance, and drive sustainable growth. Check out how AI can:

• Respond to employee inquiries

• Transform videos into processes

• Assess regulatory impact & process improvements

• Generate forms, processes, risks, regulations, KPIs & more

• Parse regulatory standards into requirements

Request Free Demo

Document, analyze, improve, digitize and monitor your business processes, risks, regulatory requirements and performance indicators within Interfacing’s Digital Twin integrated management system the Enterprise Process Center®!

Trusted by Customers Worldwide!

More than 400+ world-class enterprises and management consulting firms